Robotic arms are at the heart of modern production and manufacturing change the rules in a way previously thought to be impossible to imagine. They are able to combine the highest level of safety, precision and effectiveness. These mechanical marvels, often referred to as robot arms, are indispensable in the global manufacturing industry and are driven by the imperative necessity to cut operating costs while maintaining high standards of quality. Robotic arms are integrating into production lines to reduce cost and increase security. Explore how these innovative robotics have changed the landscape of industrial production.

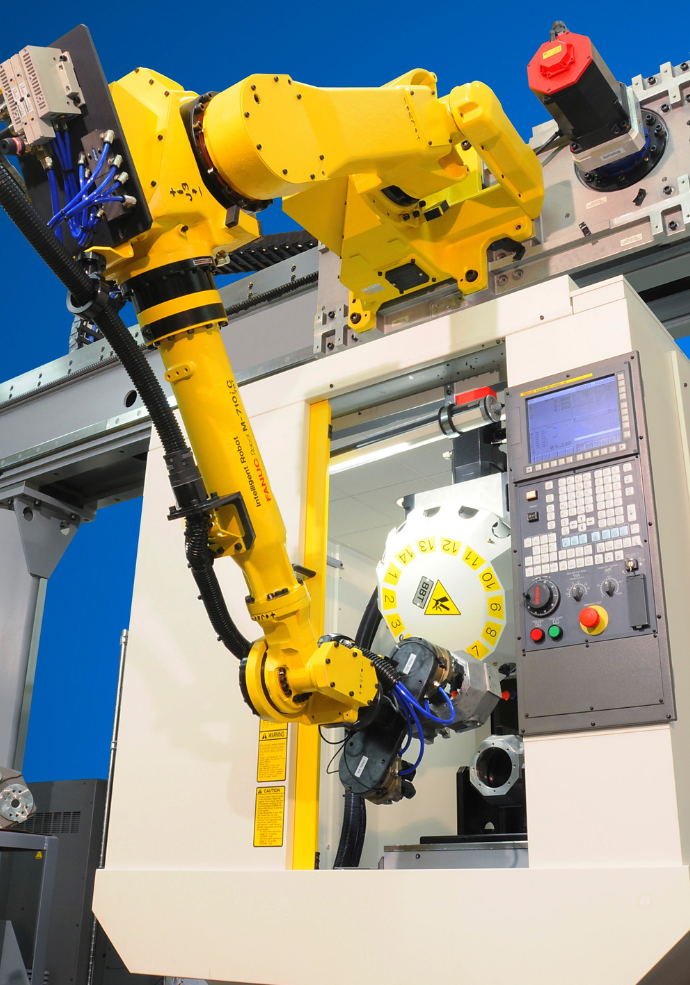

Image credit: automatedsolutions.com.au

The primary force behind the global surge in robotic arm adoption is cost efficiency. Owners of factories are under constant the pressure to decrease workplace injuries, minimize production mistakes, and reduce waste. Robotic arms were designed to solve these issues. Robots are more precise than human laborers when it comes to completing repetitive tasks, reducing costs and avoiding costly errors. Robotic arms are used in large-scale industries for example, the automotive industry, to ensure perfect assembly. This accuracy can result in substantial savings, as fewer defective parts means less rework and waste.

The safety of robot arms is also an essential element. Numerous manufacturing tasks, like handling hazardous materials or using heavy machinery could be hazardous for workers. By using robot arms, companies can eliminate workers from dangerous areas. This lowers the risk of workplace injuries. A robotic arm, designed as a kinematic chain of moving joints, mimics the functions of an arm, but is not at the danger of physical injury. The machines come with robotic hands, or programmable end-effectors. They are capable of performing tasks like grasping spinning and welding in conditions that are unsafe for humans.

Robotic arms are revolutionizing diverse industries due to their adaptability. Robot arms can handle a variety of tasks. From automotive assembly, to electronic production. The programmability of these robot arms allows them to execute complicated tasks such as painting or applying fiberglass with a remarkable level of consistency. Robotic arms have transformed the process of palletizing in warehouses, automating it with speed and accuracy. Automation not only improves efficiency but also increases reliability since robot arms can work without tiring.

One of the most exciting innovations in this area is the growth of collaborative robots also known as cobots. These robots are able to work with human workers. Cobots equipped with robotic arms in contrast to traditional industrial robots, which are confined in isolated cells, are designed to work with humans in a safe and seamlessly. Cobots that have robotic arms can be used to complete routine or heavy lifting tasks in a factory that allows humans to focus on more complicated responsibilities. This collaboration increases productivity and maintains a safe workplace, since cobots can be programmed to adjust or stop their movement when someone is nearby.

Robotic arms have an enormous influence on the modern production, and not only in terms of safety or efficiency. They are crucial to industries that require high precision in tasks such as welding, assembly or material handling. Robotic arms, for instance, can be utilized to rotate and place components in assembly within the automotive industry, ensuring that they are perfectly aligned with no human intervention. In electronics, robots are used to handle delicate components, which decreases damage and increases the quality of output.

Robotic arms are expected to gain importance as industries grow. Their ability to lower costs, improve safety and be able to adapt to a variety of tasks positions them as an essential element of the future of manufacturing. Robot arms, which combine modern technology with human imagination is not just a tool and tools, but are actually partners in progress. They are the engine behind forward the pace of innovation and change the way the world is constructed.